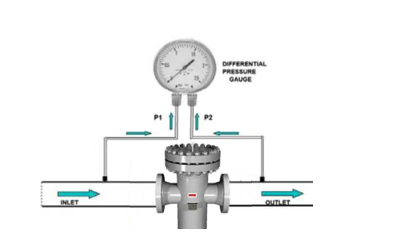

BE CAREFUL WITH THE DIFFERENTIAL PRESSURE

(PRESSURE DROP)

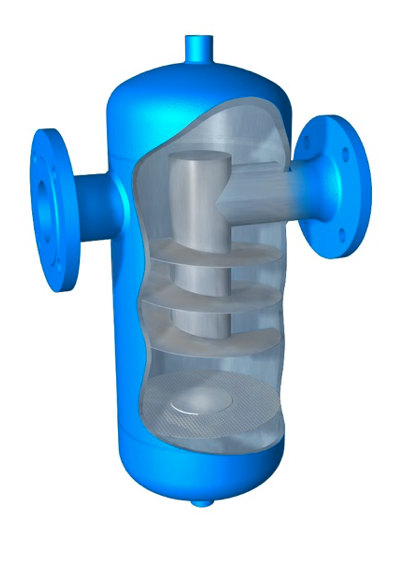

For maximum Strainer efficiency, a differential pressure gauge installed at the inlet and outlet will indicate pressure drop due to “Dirt” clogging and can be used as a guide to determine when cleaning is required typically when the differential pressure reaches between 5-10 psi, the screen must be cleaned.

But each installation must have its maintenance plan established for its equipment, taking into account each characteristic of its installed elements vs. its process.

The Strainer screen should be cleaned regularly, not when it becomes clogged,

to ensure that they are not damaged by high differential pressure

Another reason for frequent cleaning is a phenomenon known as “Runaway Buildup” and is that as dirt builds up on the screen and when the mesh or line starts as a low slope, but as the screen becomes more clogged and more, it turns up faster and faster

As dirt accumulates, the free open area in the basket becomes smaller and smaller until it breaks.