BUTTERFLY VALVES TERMINOLOGY

(differentiate between the three offsets)

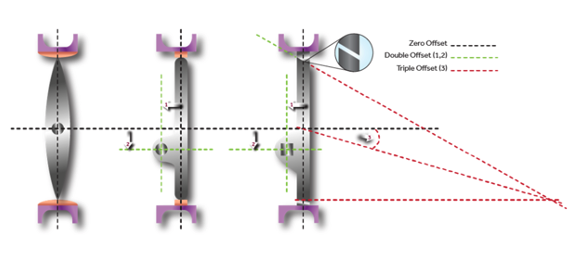

Zero Offset ( or Centered )

The stem and disc are centered in the seat of the valve, all of which are centered in the body of the valve. The disc is in constant contact with the seat.

Double Offset Butterfly Valve ( Or eccentric )

This popular type of valve is also known as a high performance butterfly valve. This valve has two stems offset from the center. This creates a cam action during the application’s process.

- 1st offset: The axis of the shaft is behind the centerline of the sealing point of the disc to seat.

- 2nd offset: The axis of the shaft is eccentric to the center of the valve/pipe line.

Triple Offset Butterfly Valve ( Or Tri-eccentric )

With the triple Offset Butterfly Valve there are three offsets. Two are placed in a similar position to the double offset butterfly valve, while the third offset is the geometry of the seating surface, creating a type of cone shape of the disc and seat. This cone angle, along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction.

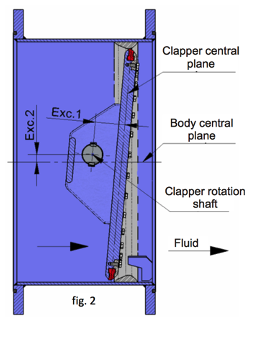

The main characteristic of double eccentric butterfly design.

The rotation shaft is offset from the central plane of the clapper (Exc.1), and in turn is also offset from the central plane of the valve body

(Exc.2), thus obtaining double eccentricity (Fig. 2) A highly effective sealing system is achieved thanks to this double eccentricity.

As soon as the valve starts to open, the elastomer seal is no longer pressed and does not come into contact with the body. For this

reason the seal is not pressed until the moment of sealing, this avoiding any contact and extending its working life.

Furthermore, since the rotation shaft is offset from the central plane of the body (Exc.2), the flow always tends to shut off the

valve; this is a big advantage when the valve operates as a safety valve in emergency situations