Steam Separators

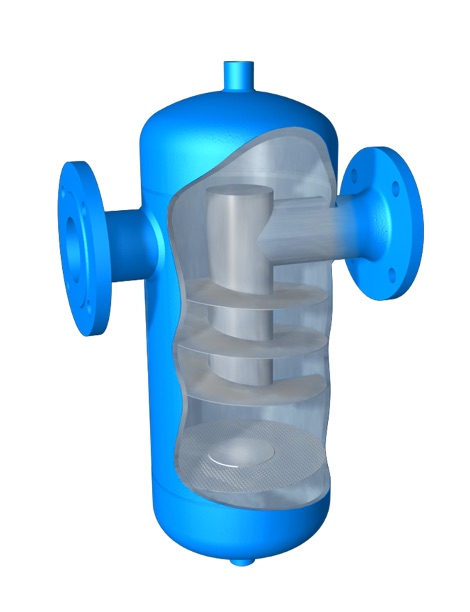

High efficiency Centrifugal Steam Separators designed to trap and remove liquid droplets that are in steam in order to obtain high-quality (dry) steam.

Recommended for installation on main steam pipelines in front of pressure reducers and other control devices, as well as flow meters

Produced 100% by us with European Raw Material and fully traceability CE/ PED 2014/68/UE certified.

Description

Separators HE-CSS of centrifugal type are designed to trap and remove liquid droplets that are in steam in order to obtain high-quality (dry) steam. They are especially recommended for installation on main steam pipelines in front of pressure reducers and other control devices, as well as flow meters. Installing a separator completely eliminates the transmission of water hammer. Also suitable for removing condensate in compressed air systems.

The condensate formed as a result of separation is removed through the drain pipe of the separator using a condensate drain unit.

It is recommended to select the separator diameter equal to the steam pipeline diameter. It has a bottom threaded (optionally flanged) hole for connecting a condensate drain unit and an upper hole for connecting an air vent.

Principle of operation

When steam or compressed air enters the separator, centrifugal impact forces and the effect of rotation separate particles with a high specific gravity such as water and oil droplets, moisture in suspensions, dirt and films.

Application

Steam, compressed air, gases

Options

- Connection: flanged

- Dimensions: DN15…DN200

- Temperature: -10… + 300°С

- Nominal pressure: standard – 16 bar (25 and 40 bar – on request)

- Installation: horizontal, drain pipe down. The formed condensate is removed through the drain pipe of the separator using the condensate drain unit

Materials

carbon steel (stainless steel on request) .

Size selection

It is recommended to select the separator diameter equal to the steam pipeline diameter. Separator pressure losses can be neglected at the recommended optimum travel speeds. Steam speed is optimal – 20-40 m/s, minimum – 15 m/s.